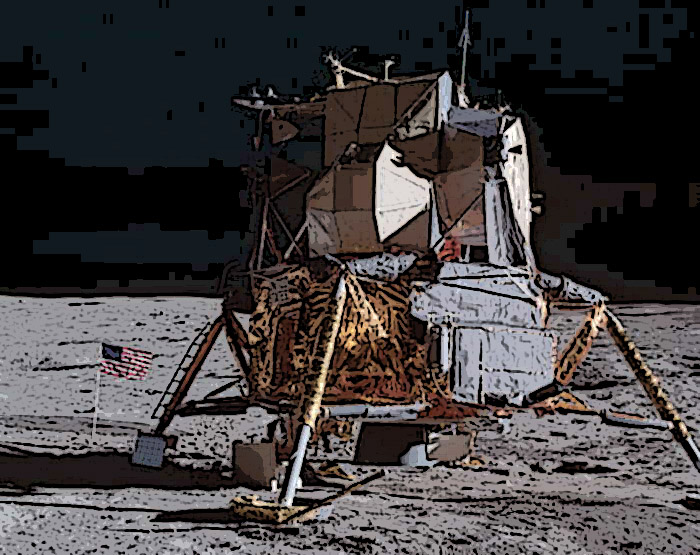

Soms zit er een enorm risico in nietige feiten. Dat soort zaken is helaas nooit voor 100% te voorzien. J.K. Kelly geeft in “Moon Lander, How We Developed the Apollo Lunar Module” dit voorbeeld van een minimale wijziging in een systeem met grote gevolgen.

Henry Graf became obsessed with finding the cause of this failure. He led his engineering and quality staff through a minute examination of every step in the manufacturing process, starting with the receipt of the titanium forgings and the quality pedigree that accompanied them. At each step of the process, they looked at what had been done on the failed tank, and asked whether anything in this step was different from their process on previous tanks. Graf’s careful detective work paid off, discovering a cause so trivial that a less observant investigator would surely have overlooked it. Graf noticed one minor difference in the process for this tank and those that had preceded it: instead of using new cloth pads to wipe the tank surfaces prior to welding, washed, reused cloths were employed. Examination of the washed cloths showed traces of detergent, and test samples that were wiped with them failed under combined stress and humidity testing. The trace detergent attacked titanium! There could be no more gripping example of the extreme sensitivity of highly stressed tank material and welds to contamination.

"Moon Lander, How We Developed the Apollo Lunar Module” bij bol.com